Fire-resistant cable management systems

We represent MP Bolagen Industri Ab’s cable management systems in Finland. The top-of-the-range products are manufactured and stored in a factory in Vetlanda, Sweden. You can order them through electrical supply stores. Legrand experts will be happy to help with any questions you may have about the products or their selection.

You’ll find the following among our range of fire-rated products:

- Cable ladders

- Trays

- Luminaire rails

- Wire mesh trays

When designing fire-rated installations, also check the manufacturer’s specific requirements below.

Regulation (EU) No 305/2011 on the marketing of construction products also applies to wiring and cable management products, although there is currently no harmonised European standard for them. As a result in Finland, the national requirements set out in the standard publication SFS 6000-5-55:2022 apply. It contains general requirements for security systems, the selection and installation of power supply systems, and power supplies for security systems.

There is currently no harmonised European standard for cable management systems, so the performance in case of fire is declared by the manufacturer on the basis of the results of fire resistance tests according to European standards EN 1361-1 and EN 1361-2. Installations must be carried out in accordance with both the manufacturer’s specific instructions and national installation regulations.

When carrying out fire-resistant installations, the following requirements must be met:

- All components must be approved by the manufacturer for the required fire rating.

- The mounting structures must be fire-resistant and must be able to withstand the load of the installed components even during a fire.

- Security structures should be installed above other installations, or alternatively they should be able to withstand the weight of any structures above them that may fall on them.

To achieve the R60 fire classification, it is also required that:

- For cable ladder installations (200 mm – 600 mm), the flat maximum load is 20 kg per metre, with a maximum support spacing of 1.5 m. Cables in vertical trays must be fixed at intervals of no more than 300 mm.

- For wire mesh tray installations (55 mm – 400 mm), the flat maximum load is 10 kg per metre, with a maximum support spacing of 1.5 m. Cables in vertical trays must be fixed at intervals of no more than 300 mm.

- The maximum uniform load for horizontal tray installations (100 mm – 400 mm) is 10 kg per metre, with a maximum support spacing of 1.5 m.

- The maximum uniform load for luminaire rail installations (75 mm – 100 mm) is 10 kg per metre, with a maximum spacing of 1.5 m.

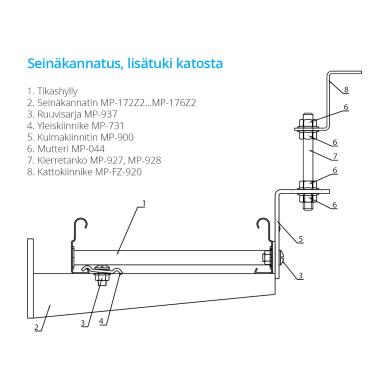

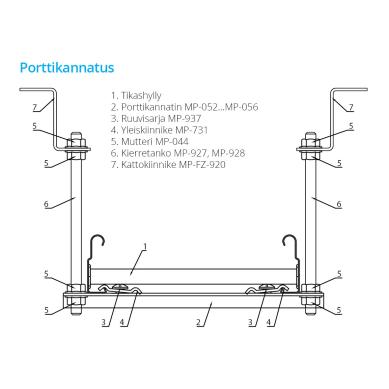

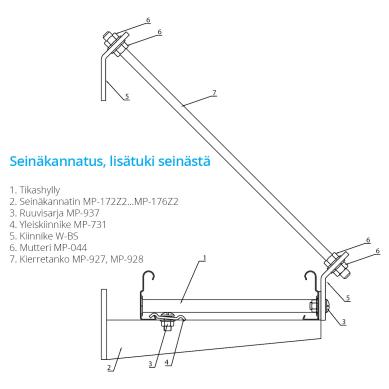

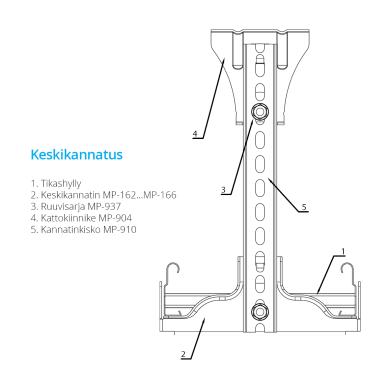

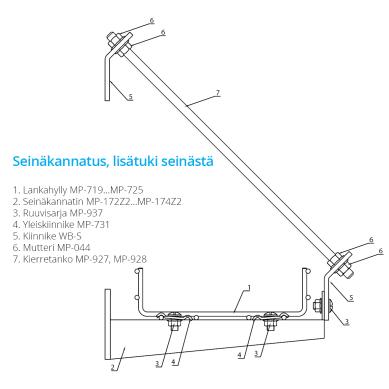

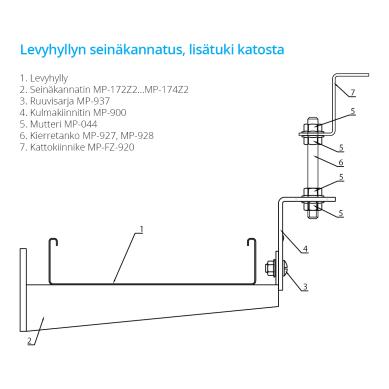

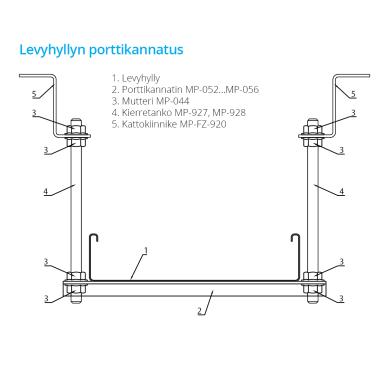

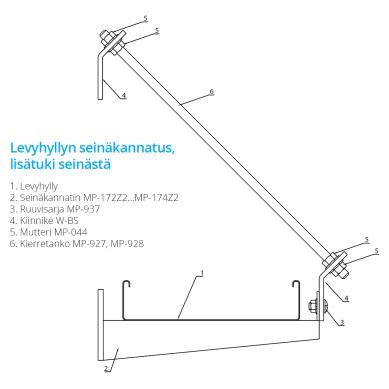

Support methods for fire-rated installations

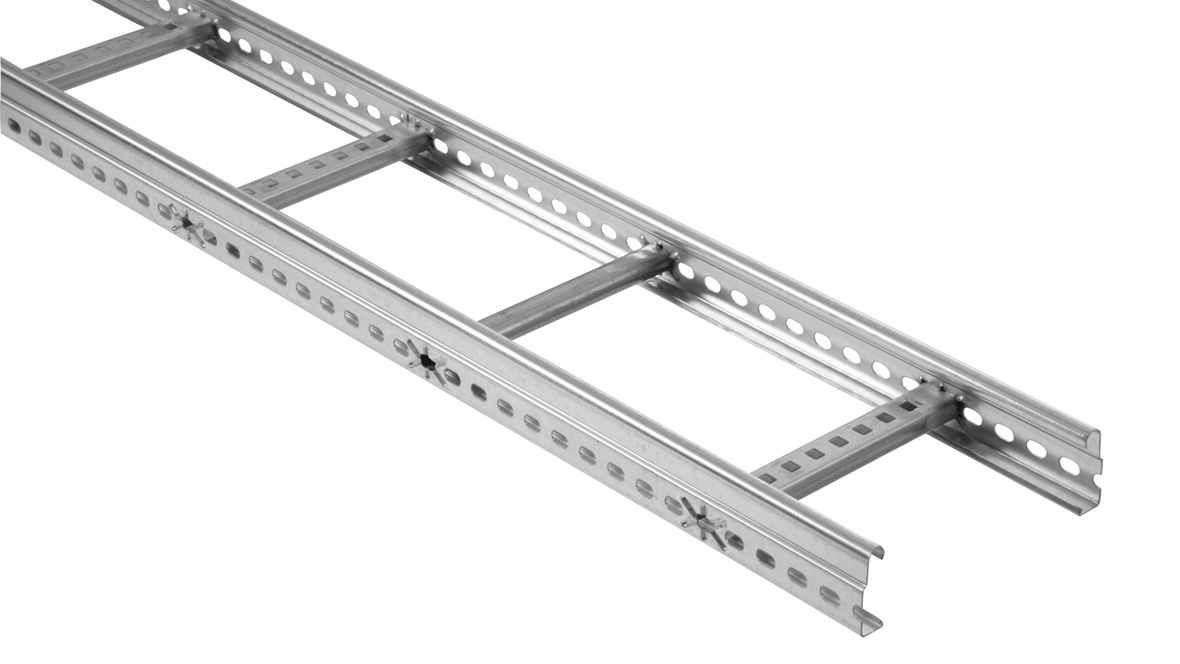

Cable ladders

- The maximum load for cable ladders is 20 kg per metre

- Maximum support spacing 1.5 m

- Widths 200 mm – 600 mm

- Fixing of vertical shelves to the wall at intervals of 1.0 metres and to the floor. Fixing of the cables with arch straps to each rung, fixing spacing of 250 mm.

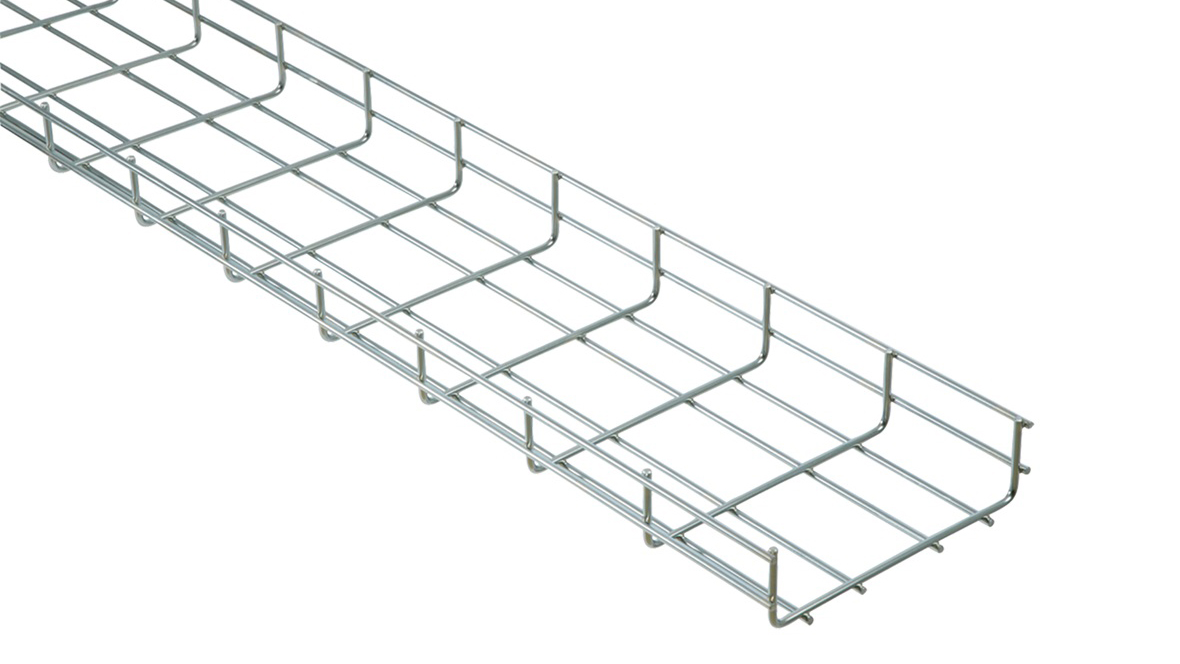

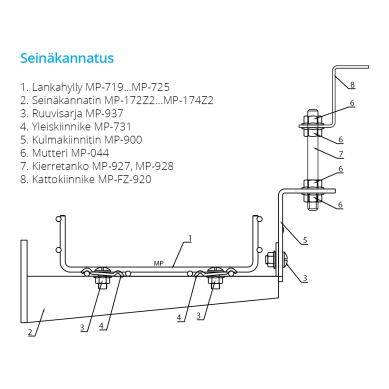

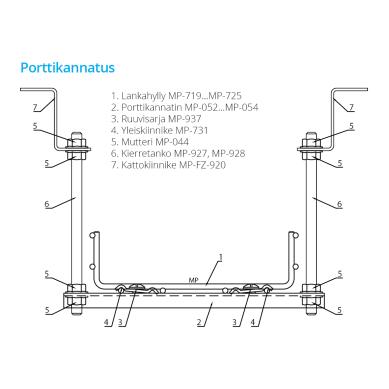

Wire mesh trays

- The maximum load for wire mesh trays is 10 kg per metre

- Maximum support spacing 1.5 m

- Widths 55 mm – 400 mm

Horizontal trays and luminaire rails

- The maximum load of the trays is 10 kg per metre

- Maximum support spacing 1.5 m

- Widths on horizontal trays 100 mm – 400 mm

- Widths on luminaire rails 75 mm – 100 mm

Fire class of the building

The building’s fire classes are P1, P2 and P3. The load-bearing structures of a P1 class building are assumed to be able to withstand a fire without collapsing. There is no limit to the size of a building in this class and the number of people it can accommodate.

The structural requirements for a P2 class building may be lower than those for a P1 class building. An adequate level of safety is achieved by imposing requirements, in particular for the properties of surfaces and for equipment that improves fire safety. The size of such a building and the number of persons are limited depending on how the building is used.

There are no specific requirements for the load-bearing structures of a P3 class building in terms of fire resistance. In such a building, an adequate level of safety is achieved by limiting its size and the number of occupants, depending on the type of use.

Provided that the spread of fire is prevented, different parts of a building may belong to different fire classes. However, the exits to the parts separated by a firewall must be constructed separately so that any door in the firewall need not be used in the event of a fire.

Load-bearing and compartmentalising building elements are classified according to their resistance to fire. The requirements prescribed for building elements are described using the symbols R, I and E, which respectively refer to load-bearing capacity, insulation and integrity. After the symbol used, the fire resistance time in minutes is indicated by one of the following figures: 15, 30, 45, 60, 90, 120, 180 or 240. The resulting marking, i.e. the combination of the uppercase letter and figure, is the fire class of the building. A load-bearing classification in the event of a fire is typically required for cable management systems.

Cable trays and their mounting parts are made of steel. Although steel is classified as a non-combustible material, its structural strength is severely reduced at temperatures above 450 °C. MP Bolagen Industri Ab has tested its cable ladder and wire mesh tray products at the SP Technical Research Institute of Sweden in accordance with the requirements of European standards EN 1361-1 and EN 1361-2.