Industrial solutions for demanding conditions

We offer high-quality Ensto enclosure solutions and Ensto industrial components for the most demanding environments. We are a reliable and flexible partner with highly skilled staff and an innovative design department, as well as expertise in a wide range of applications and raw materials including plastics and metals. We are true professionals – you can rely on our skills, consistently high quality and financial stability.

Ensto solutions have been developed for demanding industrial environments where effective protection and extreme durability are indispensable. We offer customised enclosure solutions in addition to the standard high-quality Ensto enclosures. Our range of industrial components includes connectors, switches, fuse bases and junction boxes used by the world’s leading equipment manufacturers.

With almost 60 years of experience, we are a highly professional solutions provider for the electrical industry. Ensto’s products are designed and tested to suit a wide range of applications and demanding environments, and meet the most stringent quality and operational requirements in the industry.

Customised design services

Our innovative experts will be happy to assist your design department in sourcing cost-effective Ensto enclosure solutions for your particular needs.

This will help you save resources and optimise your processes.

All Ensto enclosures and components meet the highest international quality standards. Our proven efficiency and certified quality are based on our well-equipped in-house laboratories and the highly reputable external laboratories we use for certification testing.

What do you need?

Cost-effective solutions

Our experts will help you source and design safer and more cost-effective Ensto solutions, tailored specifically to your needs.

Customised solutions

Our experienced design team will help your product designers create enclosures to meet your particular requirements. Our expertise includes technical documentation, 3D modelling and fast prototyping.

Reliable operations

We have solid expertise in the materials we use, enabling us to offer our end customers extremely reliable solutions. We always choose the materials with the customer, ensuring the best and safest manufacturability and technical performance of Ensto products.

Design files

We support the customer’s end-product design process by providing design files for both our standard and customised products. The available file formats are PDF, DWG, DXF, STEP, and separate zip-packed STEP files for software such as E3.

Customised standard enclosures

Machining

We manufacture Ensto plastic enclosures with technologically advanced modular injection moulding, which allows for the cost-effective production of customised enclosures. Ensto enclosures can be fully machined to customer requirements, including all openings, drillings and threads. We can also offer customised tools for large production runs.

We use Coboflex and Fanuc robot units to customise Ensto our plastic enclosures.

Colour services

Our in-house painting service enables cost-efficient painting of enclosures, even in small batches. All Ensto enclosures can be painted in any colour from the RAL colour chart. Ensto plastic enclosures are painted with a silicone-free, semi-gloss 2K polyurethane topcoat that provides exceptionally long-lasting chemical protection and impact resistance.

Ensto’s standard plastic enclosures can also be manufactured directly in a specific colour at the customer’s request. Extrusion from coloured raw material is advantageous, especially for large orders. When made from coloured plastic, the holes and inner surfaces of the enclosure will of uniform colour.

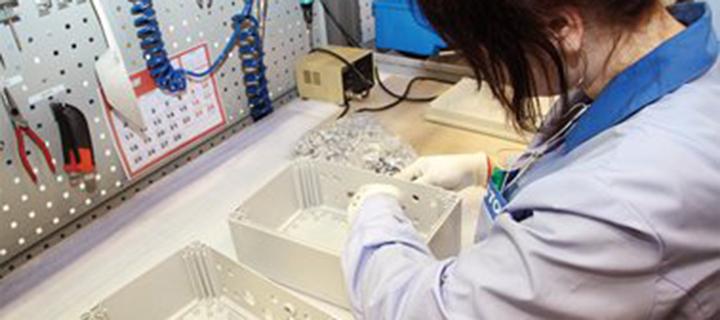

Installation of components

All Ensto enclosures can be pre-fitted at the factory with various components such as DIN rails, connectors and cable sealing clamps. We can also source third-party components, saving the customer time and energy. In addition, we offer wiring of Ensto enclosures, circuit board installations as well as integration of hardware and software.

Customer-specific enclosures

Concept design

The production of customised Ensto enclosure solutions begin with a conceptual design where the customer’s requirements and wishes are determined. We have extensive knowledge of different manufacturing methods, certifications, materials and enclosure classifications for enclosures in a wide variety of environments. We can also assemble electromechanical components into customised Ensto enclosures.

Feasibility studies

A technical feasibility study is an assessment of the manufacturing requirements and costs of a product to be designed. We listen carefully to our customers’ wishes for product design, and work closely with their R&D department to find the best possible enclosure design that is cost-effective to manufacture.

Product design

Our highly experienced designers handle the design and mechanical engineering of Ensto solutions according to the customer’s requirements. They also provide all the necessary 3D models and technical documentation. On the integration services side, our designers will draw up the necessary wiring diagrams. We can also source third-party components for Ensto enclosures.

Prototype production

We quickly produce ready-to-use samples on our own 3D printer, allowing the customer to view the product design and make the necessary changes quickly. We can also test different materials and produce silicone-based prototype series. We take the design of Ensto products seriously, and our enclosures are also stylish in appearance.

Procurement of tools

With our extensive network of partners, we can provide even the most complex injection moulds used in the manufacture of enclosures at competitive prices. The tools used in the manufacturing process are ready to use according to the customer’s requirements with the highest quality and reliability.

Guaranteeing quality

We guarantee the quality of all Ensto products and services, with extensive knowledge of the certifications and tests required to commercialise products in different countries. We work closely with the various certification authorities and help our customers obtain the right certificates with the least amount of effort. As we have many certificates for different materials, functions and models, there’s no need to test everything again. We provide all the necessary quality documentation, and can arrange quality audits if required.

Integration services

Installation and wiring of electromechanical components

We are capable of producing electromechanical installations, typically integrations of classes 1 through 4. Our assembly meets the EN 60439-1 standard for the construction of low- and medium-voltage power plants, and our production is ISO 9001:2008 quality certified.

Testing, including environmental and usability testing

We test the durability of integrated Ensto solutions and ensure that the customer receives products that are suitable for the purpose and the environment. In our test lab we can perform ingress protection and impact resistance tests (IP/IK tests), as well as test the correct functionality of the equipment when fully assembled.

Procurement of components

Ensto manufactures a wide range of electromechanical components such as connectors and switches, and mechanical components such as rails and mounting plates.

As part of our integration services, Ensto can also source third-party components for installation in Ensto enclosures. A wide network of partners and market knowledge ensure good availability of top-quality components at competitive prices.

Quality assurance

By working to international standards, we ensure the high quality of our products, both in terms of the individual components and in the total solutions we deliver. If the customer has additional requirements regarding standards and safety classes, these can be accommodated. Ensto works closely with leading testing and certification bodies such as UL Solutions, SGS and DNV.

Customised solutions

We have a long experience in customised solutions for the original equipment manufacturing industry and demanding environments. Our technical and design expertise is distinguished. We are a reliable and flexible partner and we stick to agreed deadlines. Ensto connectors are used worldwide.

In addition to standard Ensto products, we offer customised solutions. These include standard connectors with customised printing and labels, as well as products designed and produced entirely according to the customer’s needs. One example of this is the Ensto Clampo Pro – a three-pole universal connector originally designed for one of our customers, a manufacturer of inverters.

Our service offering also includes delivery in special packaging and the manufacture of Ensto products with customised labels.

Our core strengths:

- Several years of experience in customised solutions

- A highly experienced design department

- Production and assembly, including in low-cost countries

- A large range of high-quality Ensto connectors and a global customer base

Ensto services

Among our services:

- 3D modelling

- Manufacture of prototypes

- Testing

- Product marking and labelling

- Printing, e.g. company logos, instructions and symbols

- Manufacture of plastic parts from coloured plastic material

- Organisation of certification and consultation

- Manufacture and assembly

Reference

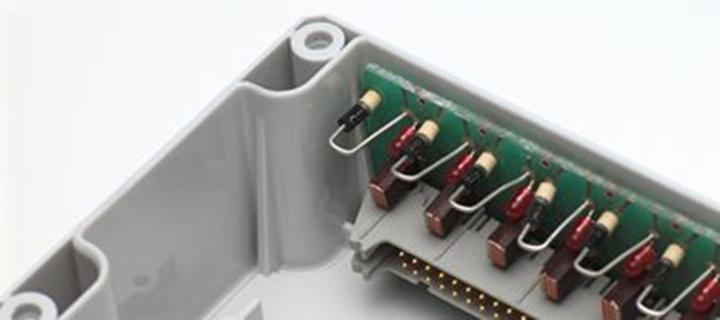

Customised Ensto connectors for Vacon

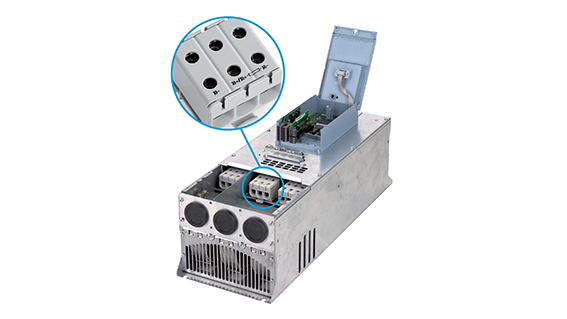

The Finnish company Vacon (now part of Danfoss Group) manufactures liquid and air-cooled low-power drives with a power range of 0.25 kW to 5 MW. The company has a global market share of 4%. These drives feature Ensto three-pole Clampo Pro connectors, designed specifically for Vacon and the AC drive industry.

Vacon products are mostly custom solutions. They offer system integrators and original equipment manufacturers different types of low-power drives based on open and uniform technology.

Vacon and Ensto began working together in 2004. Energy efficiency and sustainability are a key part of both companies’ strategies. They speak the same language and have the same mindset and approach to how they work.

The companies are often co-located around the world, simplifying collaboration processes, reducing delivery times and enabling more direct communication.